A Graphite Sulfuric Acid Dilution Cooler is a specialized device designed for the safe dilution of sulfuric acid and the subsequent cooling of the resultant mixture. This ensures that the chemical processing is carried out in an efficient and controlled manner.

支付:

TT L/C PayPal Westunion Moneygram产品起源:

China, Anhui province运输端口:

Shanghai交货时间:

1 Month量:

1包裹:

Wooden case颜色:

Customzied材料:

Graphite工作温度:

165℃工作压力:

Vertical≤0.1Mpa,Horizontal≤0.4Mpa

Product review

The graphite sulfuric acid dilution cooler is capable of diluting 98% concentrated sulfuric acid to a concentration of 50 - 60% and can also cool the diluted solution to the desired temperature within the same device.

Product advantages

The Graphite Sulfuric Acid Dilution Cooler offers a plethora of advantages. It exhibits high heat transfer efficiency, ensuring effective heat exchange during the dilution and cooling processes. Its excellent corrosion resistance makes it highly suitable for handling the corrosive nature of sulfuric acid, thereby enhancing its durability. The cooler operates reliably, minimizing the risk of malfunctions and ensuring consistent performance.

It achieves uniform dilution of the sulfuric acid, resulting in a homogeneous mixture. Simultaneously, it provides good temperature control, allowing for precise regulation of the cooling process to reach the desired temperature. With a long service life, this cooler can endure extended periods of operation without significant degradation.

The maintenance cost associated with the Graphite Sulfuric Acid Dilution Cooler is relatively low, reducing operational expenses over time. Its compact structure makes it space-efficient and convenient for various installation settings. Moreover, it is easy to install, saving both time and effort during setup.

Notably, this cooler is capable of handling large volumes of sulfuric acid stably, making it an ideal choice for industrial applications where large-scale dilution and cooling are required.

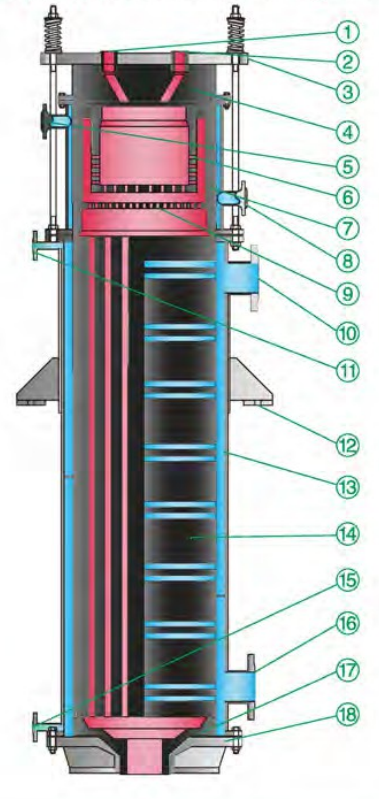

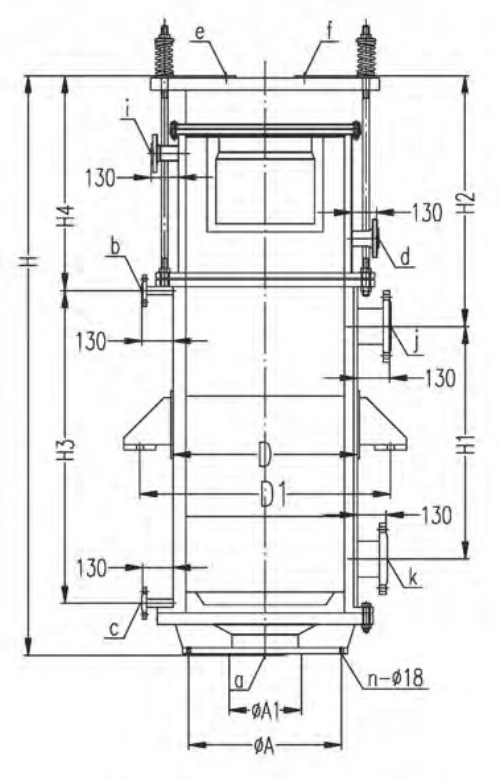

Structural diagram

| Parts details | |

| 1 | Concentrated acid inlet |

| 2 | Dilution water inlet |

| 3 | Upper cover plate of equipment |

| 4 | Graphite upper head |

| 5 | Cooling water outlet |

| 6 | Graphite mixing chamber cylinder |

| 7 | Graphite mixing outdoor cylinder |

| 8 | Cooling water inlet |

| 9 | Graphite sieve plate |

| 10 | Cooling water outlet |

| 11 | Vent |

| 12 | Equipment support |

| 13 | Shell |

| 14 | Graphite heat exchange block |

| 15 | Drain port |

| 16 | Cooling water inlet |

| 17 | Graphite lower head |

| 18 | Lower cover plate of equipment |

Others