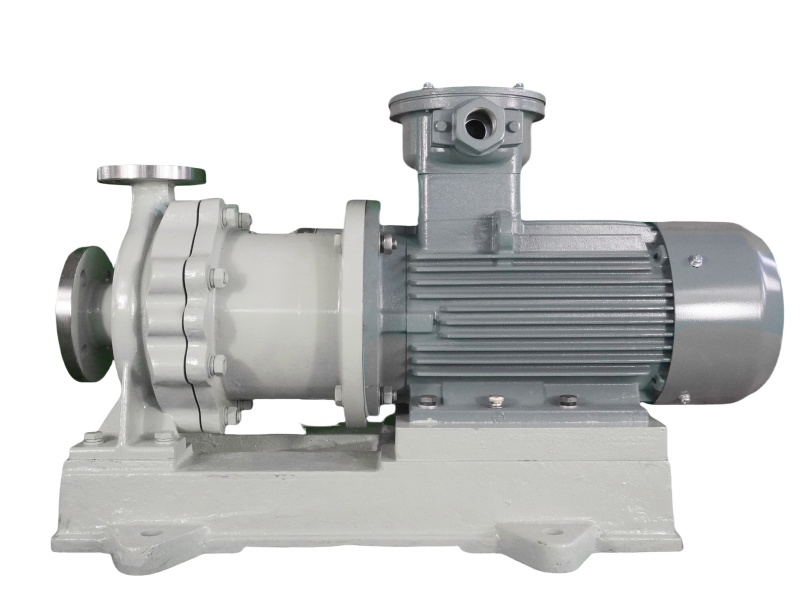

The TCH no-leakage stainless steel magnetic pump represents an advanced type of industrial pump. It is characterized by a full-seal design, which effectively eliminates the possibility of leakage. Constructed from stainless steel, it exhibits excellent corrosion resistance. The high-quality magnets incorporated within the pump ensure a reliable magnetic drive, making it well-suited for application in a diverse range of industries.

量:

1包裹:

Customzied颜色:

Customzied材料:

Steel工作温度:

-60 to 300 ℃,New material withstands temperatures up to 450°C工作压力:

1.6 to 6.3 MPa

Product overview

The TCH stainless steel magnetic pump represents an upgrade and innovation built upon the foundation of the TC pump. It has been independently developed and designed as the third generation of a new industrial pump, featuring full sealing, zero leakage, and no pollution.

This pump applies the principle of magnetomechanics, with the medium being enclosed within the static isolation sleeve. Through this design, it is able to achieve non-contact torque transmission. By eliminating the shaft seal device (such as packing seal or mechanical seal) commonly found in traditional centrifugal pumps and replacing the dynamic seal with a static seal, a new type of fully sealed, leak-free magnetic pump has been successfully created.

Product advantages

1. The magnet is composed of ferrite magnet, Nd-Fe-B, and samarium cobalt. It exhibits excellent magnetic properties, high temperature resistance, and no demagnetization.

2. The shaft sleeve and sliding bearing are fabricated from highly wear-resistant materials such as silicon carbide, graphite, and tetrafluoro. Additionally, they are equipped with lubrication grooves, which effectively ensure the pump's service life.

3. It is completely leak-free. All sealing points are sealed by closed static seals and driven by a magnetic coupling. There is no need for a nitrogen seal, making it safe, economical, and efficient.

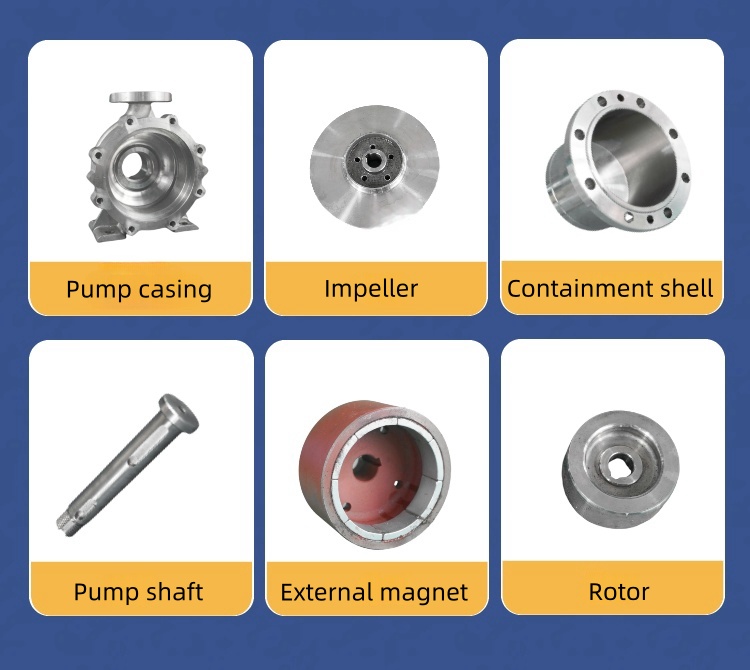

Material List

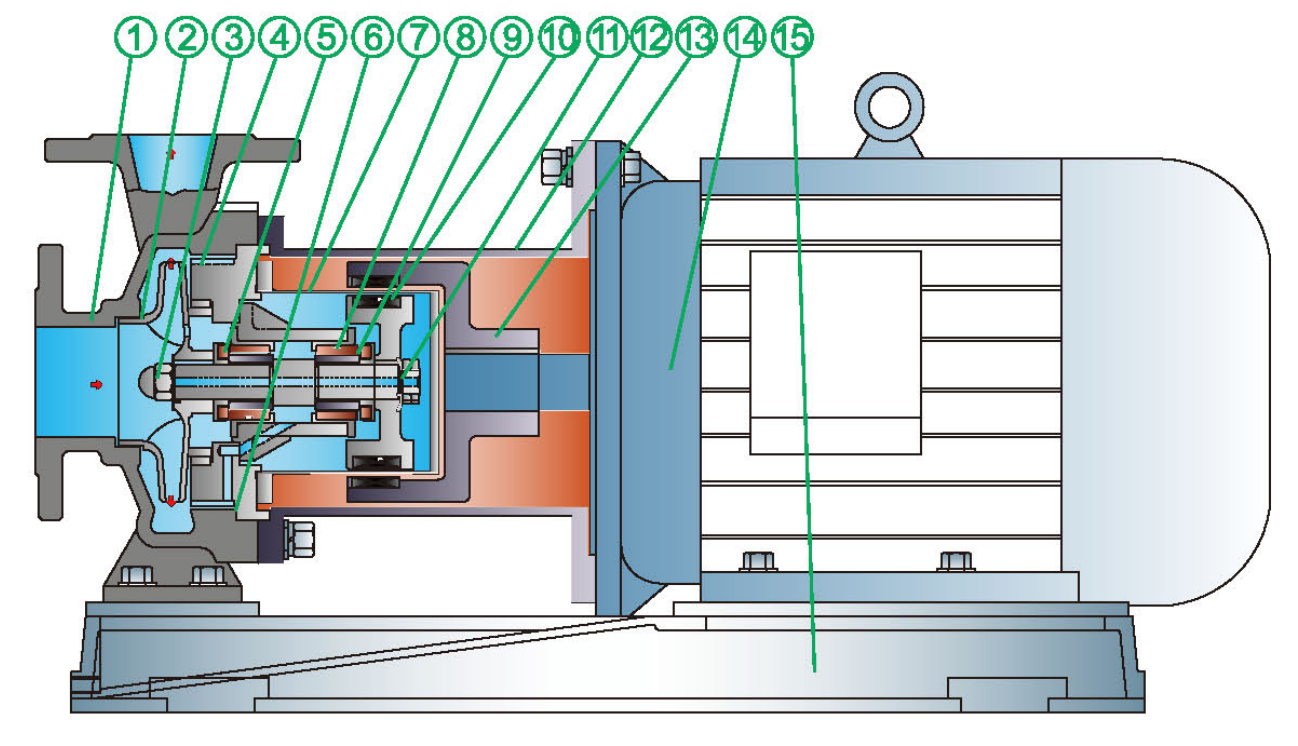

| Part | Material | Part | Material | Part | Material |

| ① Pump body | 304/316/316L | ⑥ Seal ring | Tetrafluoro | ⑪ Pump shaft | 304/316/316L/321 |

| ② Impeller | 304/316/316L | ⑦ Sealing sleeve | 316L/TA2/HC276 | ⑫ Bracket | Permenant magnet/HT200 |

| ③ Impeller nut | 304/316/316L | ⑧ Plain bearing assembly | Carbon fiber/SSIC/Cemented carbide | ⑬ Extemal magnet assembly | HT250/permenant magnet |

| ④ Pump cover | 304/316/316L | ⑨ Thrust disc assembly | Carbon fiber/SSIC/Cemented carbide | ⑭ ELectric machinery | Per clients requested |

| ⑤ Thrust disc assembly | Carbon fiber/SSIC/Cemented carbide | ⑩ Internal magnetic assembly | Permenant magnet/304/316/316L/321 | ⑮ Plate | HT200/A3/Channel steel |

Structural diagram

Performance Data

| Type | Rated power | Rated flow | Rated head | Voltage | Pump casing material | Suction |

| 25-20-125 | 1.5 | 2.5 | 20 | 380V | 304/316/316L | 25*20 |

| 25-20-160 | 2.2 | 2.5 | 32 | 380V | 304/316/316L | 25*20 |

| 25-20-200 | 5.5 | 2.5 | 50 | 380V | 304/316/316L | 25*20 |

| 25-20-250 | 11 | 2.5 | 80 | 380V | 304/316/316L | |

| 32-20-125 | 1.5 | 3.2 | 20 | 380V | 304/316/316L | 32*20 |

| 32-20-160 | 2.2 | 3.2 | 32 | 380V | 304/316/316L | 32*20 |

| 32-20-200 | 5.5 | 3.2 | 50 | 380V | 304/316/316L | 32*20 |

| 32-20-250 | 11 | 3.2 | 80 | 380V | 304/316/316L | 32*20 |

| 40-25-125 | 2.2 | 6.3 | 20 | 380V | 304/316/316L | 40*25 |

| 40-25-160 | 3 | 6.3 | 32 | 380V | 304/316/316L | 40*25 |

| 40-25-200 | 5.5 | 6.3 | 50 | 380V | 304/316/316L | 40*25 |

| 40-25-250 | 15 | 6.3 | 80 | 380V | 304/316/316L | 40*25 |

| 40-25-315 | 6.3 | 125 | 380V | 304/316/316L | 40*25 | |

| 50-32-125 | 3 | 12.5 | 20 | 380V | 304/316/316L | 50*32 |

| 50-32-160 | 4 | 12.5 | 32 | 380V | 304/316/316L | 50*32 |

| 50-32-200 | 7.5 | 12.5 | 50 | 380V | 304/316/316L | 50*32 |

| 50-32-250 | 15 | 12.5 | 80 | 380V | 304/316/316L | 50*32 |

| 50-32-315 | 12.5 | 125 | 380V | 304/316/316L | 50*32 | |

| 65-50-125 | 4 | 25 | 20 | 380V | 304/316/316L | 65*50 |

| 65-50-160 | 7.5 | 25 | 32 | 380V | 304/316/316L | 65*50 |

| 65-40-200 | 15 | 25 | 50 | 380V | 304/316/316L | 65*40 |

| 65-40-250 | 22 | 25 | 80 | 380V | 304/316/316L | 65*40 |

| 65-40-315 | 37 | 25 | 125 | 380V | 304/316/316L | 65*40 |

| 65-40-400 | 25 | 380V | 304/316/316L | 65*40 | ||

| 80-65-125 | 7.5 | 50 | 20 | 380V | 304/316/316L | 80*65 |

| 80-65-160 | 15 | 50 | 32 | 380V | 304/316/316L | 80*65 |

| 80-50-200 | 18.5 | 50 | 50 | 380V | 304/316/316L | 80*50 |

| 80-50-250 | 37 | 50 | 80 | 380V | 304/316/316L | 80*50 |

| 80-50-315 | 55 | 50 | 125 | 380V | 304/316/316L | 80*50 |

| 80-50-400 | 50 | 380V | 304/316/316L | 80*50 | ||

| 100-80-125 | 15 | 100 | 20 | 380V | 304/316/316L | 100*80 |

| 100-80-160 | 22 | 100 | 32 | 380V | 304/316/316L | 100*80 |

| 100-65-200 | 37 | 100 | 50 | 380V | 304/316/316L | 100*65 |

| 100-65-250 | 45 | 100 | 80 | 380V | 304/316/316L | 100*65 |

| 100-65-315 | 75 | 100 | 125 | 380V | 304/316/316L | 100*65 |

| 100-65-400 | 100 | 380V | 304/316/316L | 100*65 | ||

| 125-80-160 | 380V | 304/316/316L | 125*80 | |||

| 125-100-200 | 55 | 200 | 50 | 380V | 304/316/316L | 125*100 |

| 125-100-250 | 75 | 200 | 80 | 380V | 304/316/316L | 125*100 |

| 125-100-315 | 22 | 100 | 32 | 380V | 304/316/316L | 125*100 |

| 125-100-400 | 37 | 100 | 50 | 380V | 304/316/316L | 125*100 |

| 150-125-250 | 22 | 200 | 20 | 380V | 304/316/316L | 150*125 |

| 150-125-315 | 45 | 200 | 32 | 380V | 304/316/316L | 150*125 |

| 150-125-400 | 55 | 200 | 50 | 380V | 304/316/316L | 150*125 |

| 200-150-250 | 55 | 400 | 20 | 380V | 304/316/316L | 200*150 |

| 200-150-315 | 75 | 400 | 32 | 380V | 304/316/316L | 200*150 |

| 200-150-400 | 110 | 400 | 50 | 380V | 304/316/316L | 200*150 |

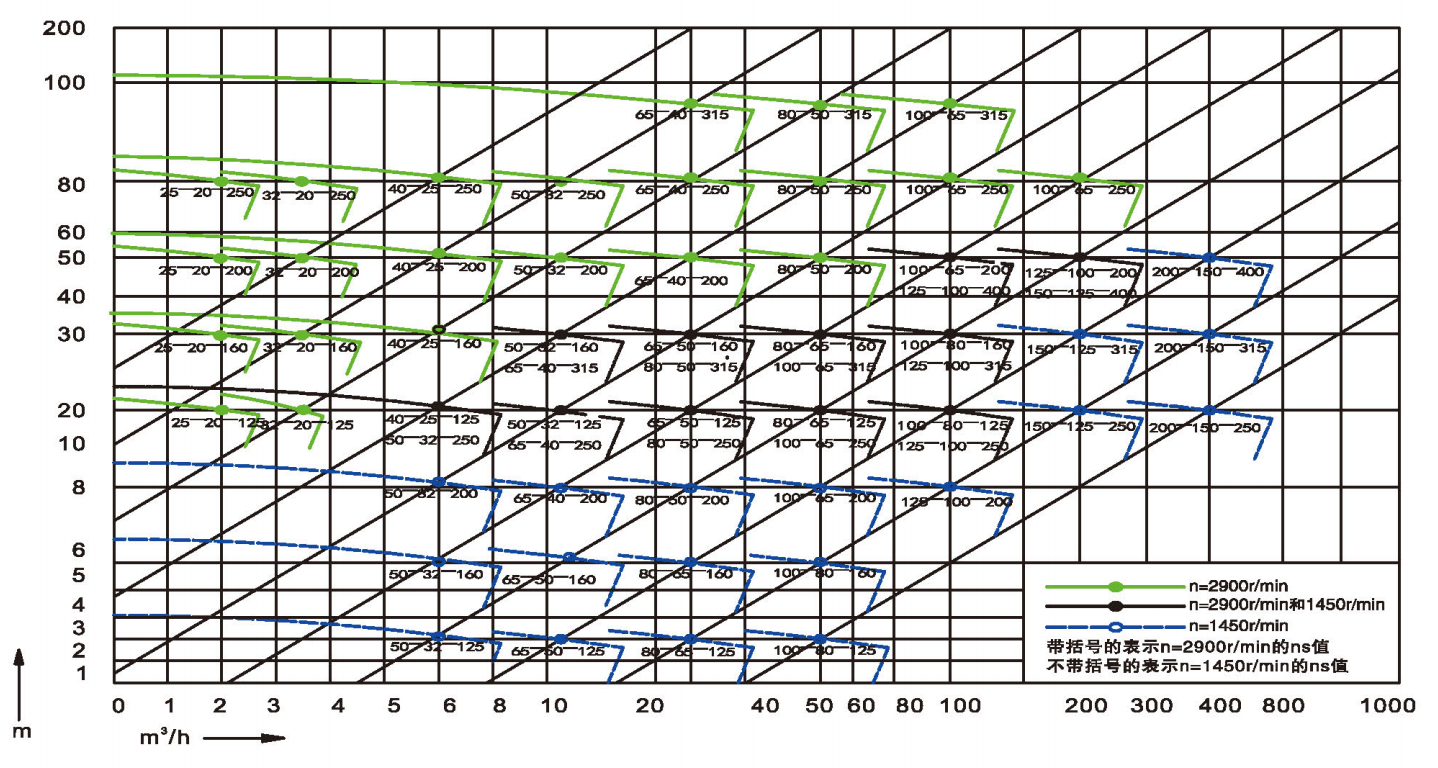

Performance range

Design pressure :1.6~6.3MPa, Flow :0.75~460m³/ h , Lift :5~125m, Power :0.55~110KW.

Applicable temperature :-60~300℃, new materials are adopted , and the temperature resistance can reach 450℃.

Product application

It is extensively utilized for transporting corrosive liquids within the production processes of various industries, such as petroleum, chemical engineering, alkali production, smelting, rare earth extraction, pesticide manufacturing, dye production, pharmaceuticals, papermaking, electroplating, and electrolysis. In particular, it is suitable for handling the transportation of flammable, explosive, volatile, toxic, high-temperature, strong alkali, and organic solvents.

Others